Introduction

Robotics engineers are professionals who design, build, and maintain robotic systems, utilizing a blend of technical expertise and innovative problem-solving skills.

Their role involves creating sophisticated robots that can perform tasks autonomously or with minimal human intervention.

Robotics engineers must actively collaborate with experts from different fields.

This teamwork is crucial for achieving success and advancing technology.

Collaboration is vital for robotics engineers as it integrates diverse expertise, enhancing the design and functionality of robotic systems.

Each project benefits from the combined knowledge and skills of different professionals, leading to more innovative and effective solutions.

By working together, teams can streamline processes, address challenges efficiently, and achieve superior results.

Robotics engineers often partner with software developers to craft and integrate control systems and algorithms that drive robotic functionality.

This collaboration ensures that robots can perform tasks accurately and efficiently.

Mechanical engineers play a crucial role as well, designing and optimizing the physical components of robots to ensure they are robust and functional.

Their expertise in materials and structural design contributes significantly to the performance and durability of robotic systems.

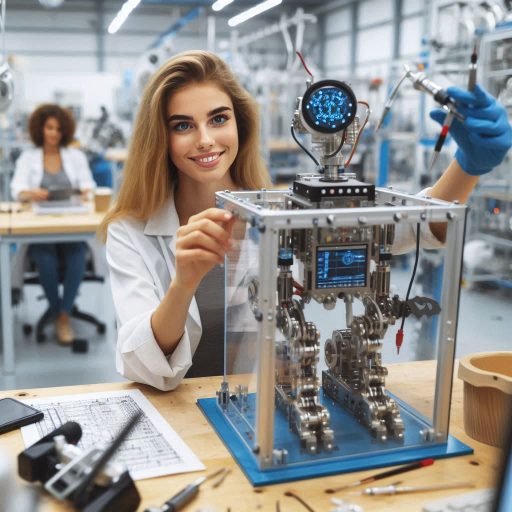

Robotics Engineers Collaborating with Software Developers

Robotics engineers and software developers work closely to create advanced robotic systems.

Their collaboration is essential for designing and developing effective robots.

By leveraging each other’s expertise, they enhance robot functionality and ensure seamless integration between hardware and software.

Designing and Developing Robotic Systems

The design process of robotic systems involves both hardware and software components.

Robotics engineers focus on the physical aspects, such as sensors, actuators, and mechanical structures.

They develop the robot’s physical capabilities to perform specific tasks.

Software developers contribute by designing the software that controls these physical components.

They write code that interprets data from sensors and instructs actuators to perform actions.

The software must be robust and efficient to handle the complex tasks required of modern robots.

Utilizing Programming Skills to Enhance Functionality

Programming plays a crucial role in enhancing robot functionality.

Software developers use their skills to create algorithms that enable robots to perform complex tasks.

This includes machine learning algorithms for adaptive behavior and real-time processing for immediate responses.

Robotics engineers and software developers collaborate to ensure that the programming effectively controls the robot’s hardware.

For instance, they work together to develop control systems that translate software commands into precise mechanical movements.

This collaboration results in robots that can navigate environments, manipulate objects, and interact with humans more effectively.

Ensuring Seamless Integration

Seamless integration between hardware and software is critical for robotic systems.

Robotics engineers and software developers must work together to ensure that all components function harmoniously.

This requires thorough testing and debugging of both hardware and software.

Key steps for ensuring seamless integration include

- Coordinated Development: Both teams need to work in parallel, updating each other on progress and changes.

- Interface Design: Clear interfaces must be defined to allow smooth communication between hardware and software components.

- System Testing: Comprehensive testing is essential to identify and resolve issues early.

This includes integration testing to verify that hardware and software interact as expected. - Iterative Improvements: Continuous feedback loops help refine both hardware and software based on testing results and performance metrics.

in essence, the collaboration between robotics engineers and software developers is vital for the successful development of robotic systems.

By combining their expertise, they create robots that are both functional and reliable.

This partnership ensures that robotic systems operate smoothly and efficiently, advancing technology in various fields.

an leverage their respective skills and expertise to create robots that are innovative, reliable, and effective in performing a wide range of tasks.

Read: Future of CAD Technician Jobs in Engineering

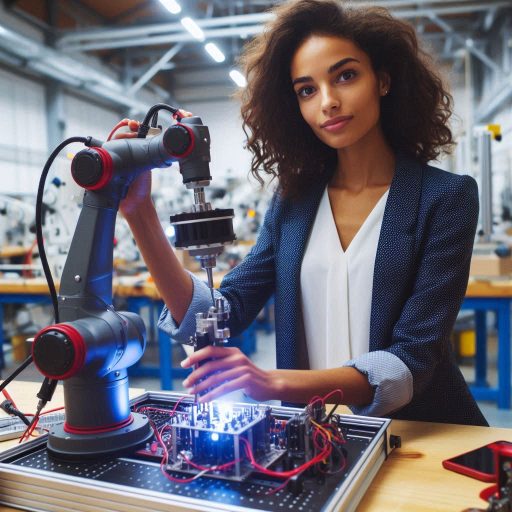

Collaboration with Mechanical Engineers

Robotics engineers frequently collaborate with mechanical engineers to design and build robotic structures and components.

This partnership is crucial for developing high-performance robots capable of handling complex tasks.

Designing and Building Robotic Structures and Components

Mechanical engineers play a vital role in designing the physical aspects of robots.

They help create detailed plans for mechanical systems, including:

- Structural Design: Mechanical engineers design the frame and body of the robot, ensuring it can withstand operational stresses.

- Actuation Systems: They develop and integrate actuators and motors that drive robotic movements.

- Component Selection: Mechanical engineers choose appropriate materials and components, balancing strength, weight, and cost.

Implementing Mechanical Principles to Optimize Robot Performance

Mechanical engineers apply core principles of mechanics to enhance robot performance.

Their expertise ensures that robots operate efficiently and effectively:

- Kinematics and Dynamics: They analyze and optimize the robot’s movement and force distribution to improve functionality.

- Thermal Management: Mechanical engineers design cooling systems to prevent overheating of components during operation.

- Vibration Analysis: They evaluate and mitigate vibrations that could affect precision and stability.

Ensuring Durability and Reliability of Robotic Systems

Ensuring the durability and reliability of robotic systems is another critical area of collaboration.

Mechanical engineers address various factors to enhance longevity and performance:

- Stress Testing: They perform rigorous testing to assess how robotic components handle real-world conditions.

- Fatigue Analysis: Mechanical engineers study material fatigue and wear to predict and prevent failures.

- Maintenance Planning: They design systems with ease of maintenance in mind, reducing downtime and extending the robot’s operational life.

In general, the collaboration between robotics and mechanical engineers is essential for the development of advanced robotic systems.

By working together, they ensure that robots are robust, efficient, and reliable.

Mechanical engineers’ expertise in designing structures, optimizing performance, and ensuring durability directly impacts the success of robotic technologies.

This teamwork fosters innovation and drives advancements in robotics, leading to more capable and reliable robots across various applications.

Read: Top Companies Hiring CAD Technicians in the USA

Integration with Electrical Engineers

Robotics engineers often collaborate closely with electrical engineers to ensure seamless integration of electrical components into robotic systems.

This partnership is crucial for creating efficient, safe, and functional robots.

Incorporating Electrical Components

Incorporating electrical components into robotic systems requires precise coordination between robotics and electrical engineers.

Key areas of focus include:

- Sensor Integration: Electrical engineers help integrate sensors into robots, ensuring accurate data collection and processing.

- Actuator Control: Electrical engineers design circuits to control actuators, enabling precise movements and functionality.

- Wiring and Connectivity: Proper wiring and connectivity are essential for ensuring that all electrical components work harmoniously.

Collaborating on Power Supply and Control Systems

Power supply and control systems are vital for the operation of robots.

Effective collaboration between robotics and electrical engineers ensures that these systems are robust and reliable.

Key collaboration areas include:

- Power Supply Design: Electrical engineers design power supply systems that provide adequate power for all robot components.

- Control System Development: Robotics engineers and electrical engineers work together to develop control systems that manage the robot’s operations.

- Battery Management: Efficient battery management is crucial for maintaining robot performance and longevity.

Electrical engineers design battery systems that ensure optimal performance.

Ensuring Safety and Efficiency

Safety and efficiency are paramount in robotic systems.

Collaboration between robotics and electrical engineers focuses on:

- Safety Standards: Electrical engineers ensure that all electrical components meet safety standards to prevent malfunctions and accidents.

- Efficiency Optimization: Engineers work together to optimize the efficiency of electrical systems, minimizing energy consumption and heat generation.

- Testing and Validation: Rigorous testing and validation processes are employed to ensure that electrical designs perform reliably under various conditions.

Key Areas of Focus

To achieve successful integration, both disciplines must focus on:

- Design Specifications: Clearly defined design specifications help align electrical and robotic engineering goals.

- Communication: Regular communication between engineers helps address potential issues and ensures smooth integration.

- Problem-Solving: Collaborative problem-solving helps overcome challenges related to electrical and robotic system interactions.

Essentially, integrating electrical components into robotic systems involves significant collaboration between robotics and electrical engineers.

Their joint efforts ensure that power supply and control systems are efficient, safe, and reliable.

Through careful planning, design, and testing, engineers create advanced robotic systems that meet both functional and safety requirements.

The success of these systems relies on the effective partnership between robotics and electrical engineering, highlighting the importance of teamwork in advancing robotics technology.

A fundamental aspect of robotics engineering that enhances the capabilities and functionality of robotic systems.

The collaboration between these professionals results in innovative solutions that drive the advancement of robotics technology.

Transform Your Career Today

Unlock a personalized career strategy that drives real results. Get tailored advice and a roadmap designed just for you.

Start NowCoordination with Industrial Engineers

Robotics engineers work closely with industrial engineers to optimize production processes in robotic manufacturing.

This collaboration aims to enhance efficiency and product quality in various manufacturing settings.

Let’s explore how robotics engineers coordinate with industrial engineers to achieve these goals.

Coordination with industrial engineers

Optimizing Production Processes for Robotic Manufacturing

- Process Analysis: Industrial engineers and robotics engineers begin by analyzing current manufacturing processes.

They identify bottlenecks and areas for improvement. - Integration Planning: Robotics engineers design and integrate robotic systems into existing workflows.

Industrial engineers ensure these systems align with production goals and constraints. - Workflow Optimization: The team focuses on refining production lines.

They adjust robotic programming and placement to streamline operations and reduce cycle times. - Efficiency Metrics: Both engineers develop and use metrics to measure production efficiency.

They track improvements and make data-driven adjustments to enhance performance.

Improving Workflow Efficiency in Robotic Work Environments

- Layout Design: Industrial engineers design optimal layouts for robotic work environments.

They position robots to maximize space and minimize unnecessary movement. - Task Allocation: Robotics engineers program robots to perform tasks with high precision and speed.

Industrial engineers ensure that task allocation maximizes overall workflow efficiency. - Interdisciplinary Meetings: Regular meetings between robotics and industrial engineers facilitate communication.

These meetings help address issues and implement solutions quickly. - Continuous Improvement: The team adopts a continuous improvement mindset.

They regularly review and adjust processes based on performance data and feedback.

Implementing Quality Control Measures to Enhance Product Output

- Quality Standards: Industrial engineers establish quality standards for products.

Robotics engineers program robots to adhere to these standards during production. - Inspection Systems: The team develops and integrates automated inspection systems.

These systems use sensors and cameras to ensure products meet quality criteria. - Defect Analysis: When defects occur, both engineers analyze the causes.

They use findings to adjust robotic systems and improve quality control measures. - Feedback Loop: A feedback loop is established between quality control and production.

This loop helps to quickly address and rectify quality issues, maintaining high output standards.

Coordination between robotics and industrial engineers optimizes production processes and improves workflow efficiency.

It also enhances quality control measures.

By working together, these professionals enhance manufacturing capabilities and ensure high-quality product output.

Their combined efforts lead to more efficient, productive, and reliable manufacturing environments, demonstrating the power of interdisciplinary collaboration.

rs is crucial in creating efficient and productive manufacturing processes that utilize the capabilities of robots effectively.

Read: Best Online Courses for CAD Technician Training

Collaboration with Healthcare Professionals

Designing Robotic Devices for Medical Applications

The collaboration between robotics engineers and healthcare professionals is pivotal in designing medical robotic devices.

This partnership begins with understanding the specific needs and challenges faced by healthcare practitioners.

Engineers work closely with doctors, surgeons, and other medical staff to identify critical areas where robotic technology can make a significant impact.

This process involves extensive discussions about the functionality required in medical robots, such as precision, flexibility, and reliability.

Designing Robotic Devices Involves

- Needs Assessment: Engaging with healthcare professionals to pinpoint precise requirements and challenges.

- Prototype Development: Creating initial prototypes based on gathered insights and specifications.

- Iterative Testing: Conducting iterative tests and simulations to refine the device.

- Feedback Integration: Incorporating feedback from medical staff to enhance the device’s effectiveness and usability.

- Regulatory Compliance: Ensuring the design meets medical device regulations and safety standards.

These steps ensure that the final product not only meets medical needs but also integrates seamlessly into existing clinical workflows.

Engineers actively seek feedback from medical professionals.

They use this input to adjust robotic devices, ensuring their practicality and benefit in real-world medical settings.

Enhancing Surgical Procedures with Robotic Assistance

Robotic systems are revolutionizing surgical procedures by providing enhanced precision and control.

In this collaboration, engineers develop sophisticated robotic systems that assist surgeons in performing complex operations.

The goal is to create robotic tools that improve surgical outcomes by offering fine motor control and reducing human error.

Key Aspects of Enhancing Surgical Procedures Include

- Precision and Control: Designing robotic systems that allow for precise movements and control, which are critical in delicate surgeries.

- Integration with Surgical Instruments: Ensuring that robotic systems can be seamlessly integrated with existing surgical instruments and tools.

- Surgeon Training: Developing comprehensive training programs to help surgeons master the use of robotic systems.

- Real-time Technical Support: Providing on-site technical support during surgeries to troubleshoot any issues that may arise.

- Post-Surgical Data Analysis: Collecting data from surgeries to analyze the performance of the robotic systems and identify areas for improvement.

This collaboration enhances the capabilities of surgeons, allowing them to perform more intricate procedures with greater confidence and efficiency.

The use of robotic assistance also often leads to faster recovery times and improved patient outcomes.

Ensuring Patient Safety and Optimal Treatment Outcomes

Ensuring patient safety is a fundamental aspect of developing and implementing medical robots.

Engineers and healthcare professionals work together to implement rigorous safety protocols and quality assurance processes.

This collaboration involves extensive testing and validation to ensure that robotic devices are reliable and safe for patient use.

Ensuring Safety and Optimal Outcomes Involves

- Safety Protocols: Developing and adhering to strict safety protocols to minimize risks associated with robotic systems.

- Continuous Monitoring: Implementing systems for real-time monitoring of robotic devices during procedures to detect any malfunctions or issues.

- Healthcare Professional Training: Providing thorough training for healthcare professionals on the safe and effective use of robotic devices.

- Feedback and Improvement: Gathering feedback from users and patients to continually improve device performance and safety features.

- Regulatory Adherence: Ensuring compliance with all relevant medical device regulations and standards.

By focusing on these aspects, robotics engineers and healthcare professionals can work together to create innovative solutions that enhance patient care.

This collaboration is crucial for advancing medical technology and achieving better treatment outcomes for patients.

To sum up, robotics engineers and healthcare professionals must collaborate closely.

They design effective medical devices, enhance surgical precision, and ensure patient safety.

Through continuous collaboration, these disciplines push the boundaries of medical technology, leading to improved healthcare solutions and patient outcomes.

e professionals is vital for advancing medical technology, improving surgical procedures, and ensuring patient safety and optimal treatment outcomes.

Read: How to Build a Strong CAD Technician Portfolio

Partnership with Automotive Engineers

Designing Self-Driving Vehicles and Autonomous Systems

Robotics engineers play a critical role in developing self-driving vehicles.

They integrate advanced robotics technology to create autonomous systems.

This involves designing sensors, cameras, and control systems.

Robotics engineers work closely with automotive engineers to ensure these systems operate safely and efficiently.

They develop algorithms that enable vehicles to make real-time decisions.

These systems must handle complex driving scenarios and adapt to dynamic environments.

The collaboration ensures that self-driving cars can navigate roads safely and respond to obstacles effectively.

Implementing Advanced Robotics Technology in the Automotive Industry

Robotics technology has revolutionized the automotive industry.

Engineers use robotics to automate manufacturing processes, improving efficiency and precision.

Robotics engineers design and deploy robotic arms for assembly lines.

These robots handle tasks like welding, painting, and component installation.

Automation reduces production costs and enhances product quality.

Robotics engineers also work on integrating robotics with automotive systems to create advanced driver-assistance systems (ADAS).

These systems enhance vehicle safety and provide features like lane-keeping assistance and adaptive cruise control.

Collaborating on Research and Development Projects for Future Innovations

Robotics engineers and automotive engineers collaborate on groundbreaking research and development projects.

They explore new technologies and innovations that drive the automotive industry forward.

Joint projects focus on developing advanced sensors and AI algorithms for autonomous vehicles.

Engineers test and refine these technologies in simulated and real-world environments.

They also investigate the integration of robotics with electric and hybrid vehicles.

Collaboration extends to exploring new materials and manufacturing techniques.

This partnership fosters innovation and accelerates the development of next-generation automotive technologies.

Key Areas of Collaboration

- Sensor Integration: Robotics engineers design sensors that automotive engineers integrate into vehicles for autonomous driving.

- Algorithm Development: Both teams develop and refine algorithms for vehicle navigation and decision-making.

- Testing and Validation: Collaborative efforts ensure rigorous testing and validation of autonomous systems in various conditions.

- Manufacturing Automation: Robotics engineers implement automation technologies in manufacturing processes to enhance efficiency and precision.

- Innovation Exploration: Joint research explores new technologies, materials, and manufacturing techniques for future vehicle models.

In review, the partnership between robotics engineers and automotive engineers is essential for advancing self-driving vehicles and automotive technologies.

Their collaboration leads to innovations that improve vehicle safety, efficiency, and performance.

By working together, these professionals drive the future of transportation, making autonomous vehicles a reality and setting new standards in the automotive industry.

Collaboration with Environmental Engineers

Developing Robotic Solutions for Environmental Monitoring and Clean-Up

Robotics engineers often partner with environmental engineers to tackle pressing ecological issues.

This collaboration focuses on creating robotic systems that monitor and clean up environmental hazards.

Key areas of development include:

- Environmental Monitoring: Robots equipped with sensors can track pollution levels, analyze water quality, and assess soil conditions.

These robots provide real-time data that helps in understanding and mitigating environmental impacts. - Clean-Up Operations: Robots designed for waste collection can remove debris from oceans and rivers.

They can also handle hazardous materials in contaminated sites, reducing human exposure to dangerous substances.

Implementing Sustainable Practices in Robotic Design and Operation

Sustainability is a core focus in the collaboration between robotics and environmental engineering.

This involves incorporating eco-friendly practices into robotic design and operation:

- Energy Efficiency: Engineers design robots that use renewable energy sources or highly efficient power systems.

Solar panels and low-energy components help minimize the carbon footprint of robotic systems. - Material Selection: The choice of materials for robotic construction prioritizes recyclability and environmental impact.

Using biodegradable or recyclable materials reduces the ecological footprint of robotic devices.

Addressing Environmental Challenges through Robotics Technology

Robotics technology plays a significant role in addressing various environmental challenges.

Collaborative efforts between robotics and environmental engineers are pivotal in this area:

- Disaster Response: Robots can be deployed to areas affected by natural disasters.

They assist in assessing damage, locating survivors, and delivering essential supplies in hazardous conditions. - Pollution Control: Advanced robots are developed to manage and reduce pollution.

For instance, robotic systems can capture airborne pollutants or treat contaminated water, contributing to cleaner environments.

Most importantly, the collaboration between robotics and environmental engineering leads to innovative solutions for monitoring, cleaning, and protecting our environment.

By integrating sustainable practices and leveraging advanced robotics technology, engineers address critical environmental challenges effectively.

This partnership not only enhances our ability to manage ecological issues but also ensures that robotic solutions contribute positively to environmental preservation.

Conclusion

Importance of Collaboration for Robotics Engineers

Robotics engineers benefit significantly from collaboration with other professionals.

This teamwork is crucial for developing advanced solutions.

Key points include:

Transform Your Career Today

Unlock a personalized career strategy that drives real results. Get tailored advice and a roadmap designed just for you.

Start Now- Enhanced Problem-Solving: Working with experts from various fields helps solve complex challenges in robotics.

- Broader Expertise: Collaboration brings in diverse skills and knowledge, enriching robotic design and functionality.

Diverse Range of Professions

Robotics engineers interact with a wide range of professions, including:

- Environmental Engineers: For designing robots that monitor and clean up environmental hazards.

- Healthcare Professionals: To create robotic devices that improve medical procedures and patient care.

- Software Developers: To enhance robotic systems with advanced software and algorithms.

Innovation and Advancement Through Teamwork

Interdisciplinary teamwork fosters innovation and technological advancement.

By combining expertise from different fields, robotics engineers push the boundaries of what robots can achieve, driving progress and solving real-world problems.